Welding & Fabrication Technology

Welding & Fabrication School

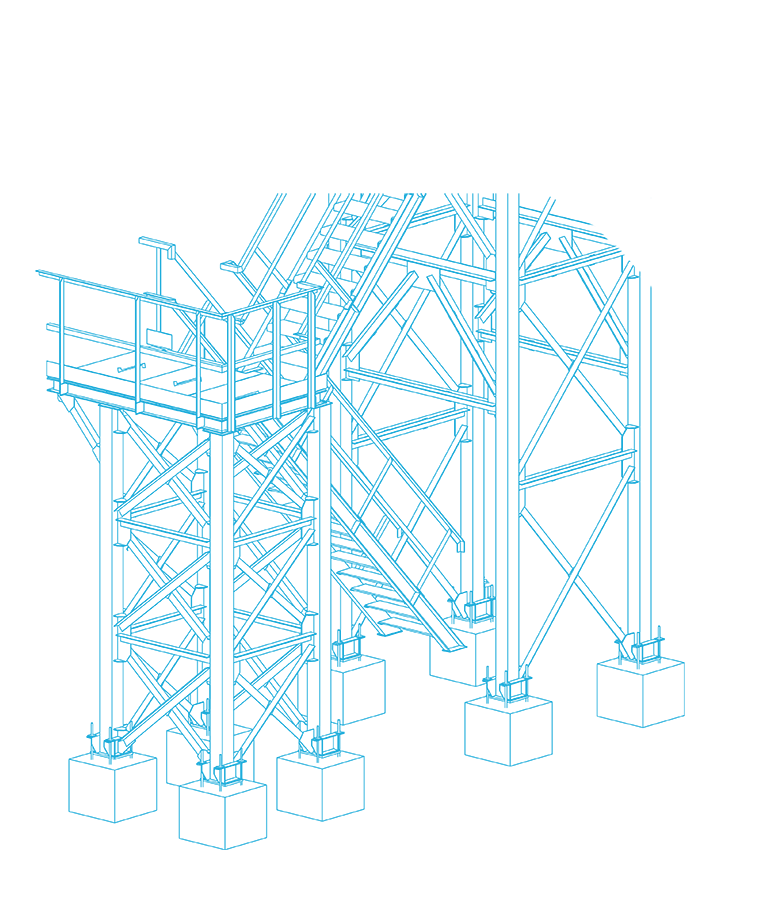

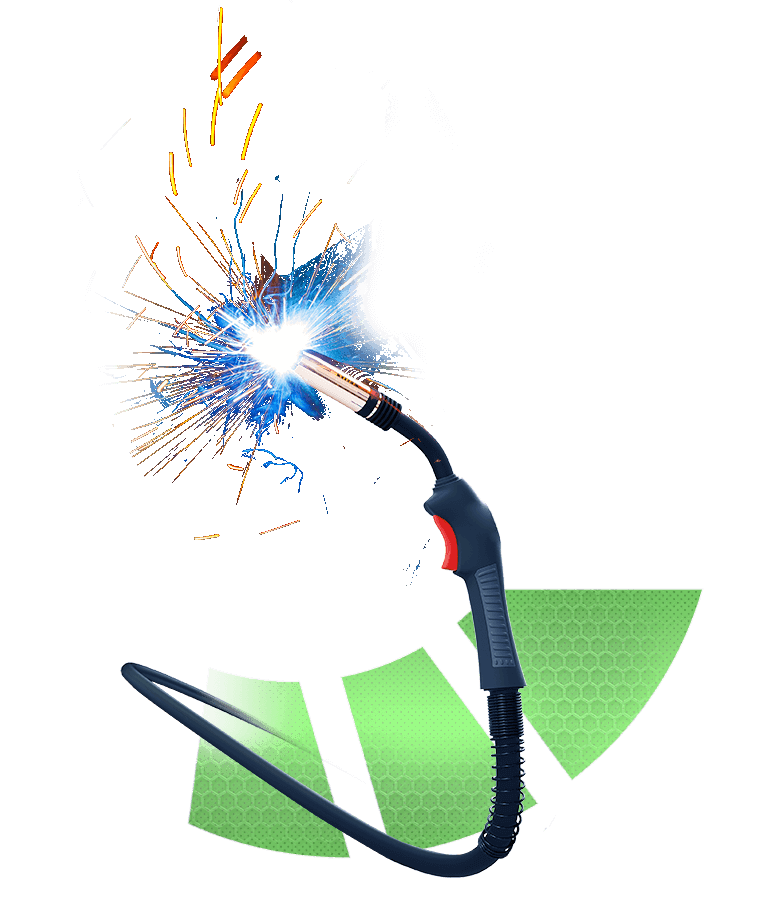

J-Tech’s Welding and Fabrication Training Program provides hands-on training using the specialized tools and equipment you’ll find in the welding industry today, including TIG welders, MIG welders, STICK welders, flux cored welders, shielding gas cylinders, consumable welding wires, welding clamps, oxy-acetylene, plasma arc cutting, carbon arc cutting, a variety of alloys, and various types of rigging equipment. We purposely design our workshop to represent the real-world welding and fabrication equipment you can expect to find in the workplace.

Welding and Fabrication

Training

Specialized Welding tech training at J-Tech

If you’re looking for a trade that is truly hands-on and in-demand, a career in welding and fabrication is a great option. One reason is the fact that so many industries rely on the skills of professional welders in their daily operations. In fact, there are about 49,200 job openings for welders every year in industries that include automotive, construction, manufacturing, and others.* All of whom need qualified welders to meet the demands of their businesses.

But at J-Tech, our goal is to help you acquire not just technical training, but also to build the essential skills that will improve your chances of advancing in the industry. That’s why our program also includes courses in Business Communications, Critical Thinking & Workplace Ethics, Career Planning, Computer Application, and Physical Sciences. We’ll also help you prepare for the various certification exams so you can hit the ground running after graduation.

*U.S. Bureau of Labor Statistics, Occupational Outlook Handbook: https://www.bls.gov/ooh/production/welders-cutters-solderers-and-brazers.htm

Ready to become a master of metal? Contact us today to learn more!

Is Hands-on Career Training Right for You?

This fun, online quiz takes 3 minutes to complete and you’ll get a personalized report. Identify your strengths and social style plus the training and positions you’re best suited for.

Admissions

Procedures

1. CONNECT

2. VISIT

3. DECIDE

Schedule Admissions Interview

Contact our admissions department and schedule your personal interview. It’s the perfect time to get all your questions answered and to learn more about the program.

Complete and Submit Forms

Fill out and submit the required forms. (Enrollment agreement, application and fee, and transcripts).

Meet with Campus Leadership Team

Get to know us and let us get to know you.

Connect with Financial Aid

Meet with one of our Financial Aid Officers to determine what financial aid you may be eligible for.

Welding & Fabrication Program

Highlights

As a graduate of the J-Tech Welding and Fabrication Technology program, you’ll be ready to get certified and get to work in an entry-level career in the welding and fabrication industry.

As a student in our Welding & Fabrication program, you'll also have access to the following benefits:

6,400 Square Foot Welding & Fabrication Workshop–with Air Conditioning!

Welding Tool & Safety Set

Valuable Insights & Networking Opportunities from J-Tech's Network of Industry Contacts

Career & Job Placement Assistance

What You'll

Learn in welding school

In just 21 months, you’ll learn:

Fundamentals of Welding

Structural Shielded Arc Welding

GAS Metal Arc Welding

Advanced GMAW

Flux Cored Arc Welding

Gas Tungsten Arc Welding

Basic Pipe Welding

Advanced Pipe Welding

Advanced GTAW

Non-Destructive Evaluation & Lab

Real-World Fundamentals

Real-World Crafting

Career

Options

Professional welders can look for work in a variety of industries including automotive, construction, manufacturing, trucking & railroads, factory production & manufacturing, ironworks, and more.

- MIG Welder

- Sheet Metal Worker

- Tool & Die Maker

- Oil Rig Welder

- Pipefitter

- Auto Body Welder

- Structural Iron & Steelworker

- Inspector

Get Your Welding & Fabrication Training Started and

Apply Now!

Ask the questions, get the answers, and get started.

What Our Grads

Have to Say

Industry

Affiliations

Put our relationships to work for your future! We partner with local employers and industry leaders to stay on the cutting edge of the welding industry.